Many drive for years without knowing much about their car's most important parts, like the valves, piston rings, and tappets. Even people who work in workshops can sometimes come across a part whose purpose is unclear or hard to remember. This is the case with the rocker arm on the engine.

With that in mind, we have put together a guide in this article to explain the different jobs that this part does while the car is running and, of course, to show how important it is to take care of the rocker's arm so that it works well and lasts a long time.

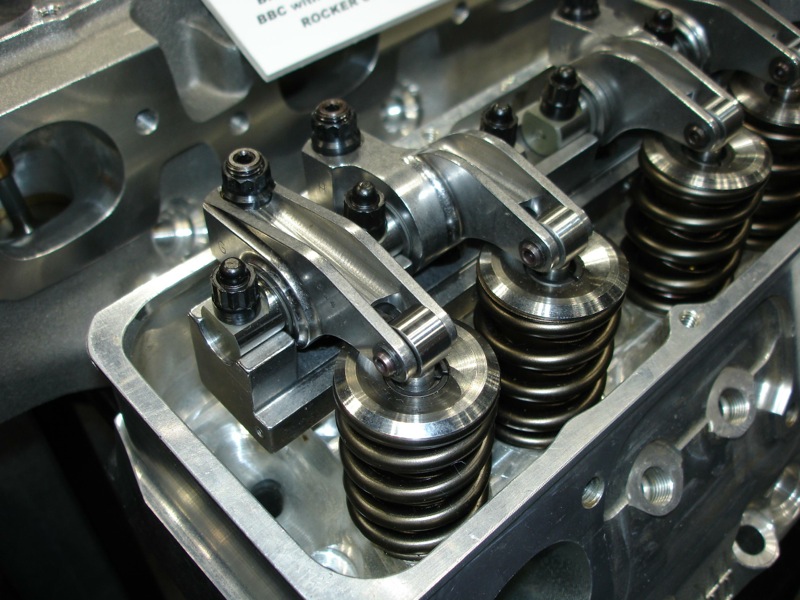

Understand the Role of the Engine Rocker Arm in Automobiles

The rocker's arm is the part that sends the movement of the camshaft to the intake and exhaust valves of the engine. This happens when the rocker's arm directly interacts with the tappets, and the shaft moves. One end of the rocker's arms connects directly to the tappet, while the other is connected to the intake and exhaust valves. This means that when the camshaft cam opens the valve, the camshaft cam triggers the rocker arm to lower one of its sides. This opens the valve and lets the mixture of air and fuel into the combustion chamber.

Cam Lobe

The camshaft is not a spherical rod; it has bumps called lobes. The lobes stick out from one side of the shaft, while the back of the shaft, opposite the lobe, does not. As the shaft turns, the side with the lobe lifts the outside end of the rocker's arm, and the side without the projection lets it fall back. Connecting rod manufacturers in India transfer the movement of the cam to the rocker's arm. Different types of cam followers depend on the car's age and manufacturer.

Ratio

Rocker's arms have ratios. The ratio is a way to measure how much leverage the arm has, which in turn tells you how much force it can put on the valve stem. The length of the arm between its center of rotation and the point where it touches the cam lobe and between its center of rotation and the top of the valve stem determines the ratio. A typical rocker arm in an automobile has a 1:1.5 ratio, which means that it moves the valve one and a half times as far as the top of the cam lobe sticks out from the camshaft.

Problems

If the top of the engine makes a tapping sound, it could be because the rocker arm is not getting enough lubrication oil. Most of the oil that goes to the top of the engine is used to lubricate the camshaft. Only a small amount goes to the rocker's arms. The top-end tapping is usually an early sign that something is wrong with the mechanical parts or the lubrication system, so getting it fixed as soon as possible is important.

Comments

Post a Comment