Engine design significantly emphasises reducing friction to maximise fuel efficiency as automakers seek out every possible technique to boost MPGs. This is evident in the increased use of low-viscosity engine fluids and engine components like low-tension piston rings. Choose the best Piston ring manufacturers in India who are selling a variety of models. Therefore, using piston rings with reduced tension can significantly reduce engine friction and, as a result, increase engine efficiency.

Below you can see about the operators should know about modern piston ring design:

Why are Piston rings needed?

A close fit of the piston into the cylinder is typically ensured by piston rings, which are typically attached to pistons and slide into ring grooves in the piston wall. Piston rings are crucial for a modern internal combustion engine to operate at peak tribological performance. These parts help to reduce blow-by, hazardous exhaust pollutants, and frictional power loss. To get the best connecting rod bearing, choose the right manufacturing company.

What is the function of Piston Rings?

An essential component of internal combustion engines is the piston ring. They oscillate up and down with the pistons. Between the piston and cylinder wall, they serve as a seal. Therefore, the smooth operation of the piston and rings is principally responsible for an engine's efficiency and economy. A connecting rod bearing is made to resist pressure from moving pistons and combustion.

Low friction should be required for both of them to work in the cylinder. Additionally, the rings must be able to survive the extreme pressures and temperatures found inside the cylinder. They ought to be powerful enough as well. Once more, they ought to endure the pressure differential between the crankcase and the combustion chamber.

The following are the functions of the piston:

- Form a seal to stop the combustion gases from leaking into the crankcase.

- Make it possible for heat to transfer from the piston crown to the cylinder walls quickly.

- Throughout the piston journey, keep enough lubricating oil on the cylinder walls.

- Maintain a consistent oil coating between the surfaces to minimise cylinder wall wear and tear.

- Block the combustion chamber from receiving lubricating oil. The carbon stains will be left behind after it eventually burns here.

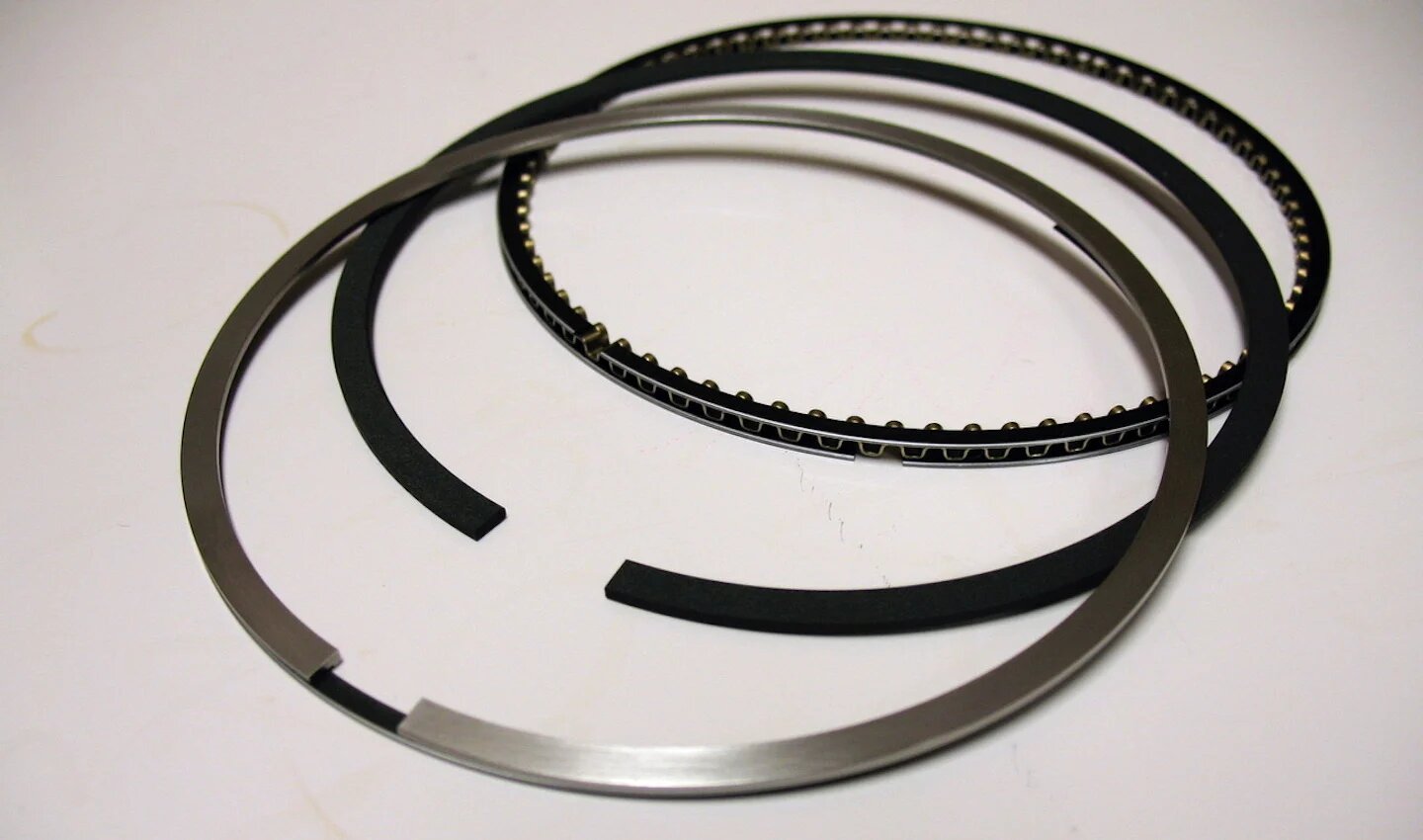

Piston Rings Construction

The piston ring is typically separately cast by manufacturers. It is meticulously machined to apply consistent pressure to the cylinder walls when in place. A gap must first be made in the ends to expand and slip over the piston head. After that, insert it into the ring groove while releasing it. Additionally, the gap closes when the piston is within the cylinder. The ring might then apply pressure on the cylinder walls.

As a result, it is essential for improved sealing. Additionally, the end gap prevents the ring's circumference from expanding at higher working temperatures. Because of this, the piston rings always run at a greater temperature than the cylinder walls. When it comes to piston ring manufacturers in India, choose the one that offers various components.

Final thoughts

Thus those mentioned above are about the operators who should know about modern piston ring design. These are the process of contemporary piston ring design, and to get the best variety of piston rings, it is excellent to pick Garima Global Pvt. Ltd.

Comments

Post a Comment