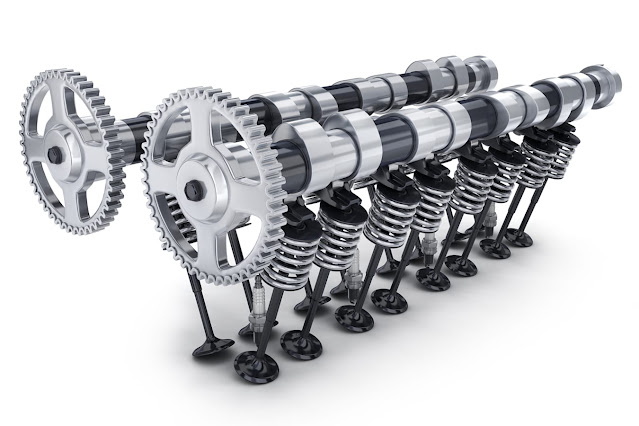

This blog will teach you the basics of an engine valve. It will cover how they work, and you can use this information to understand better how engines function and why it is important to have a well-maintained engine.

How Do Valves In An Engine Work?

The fuel intake into the engine and the exhaust gas output are the engine valve's responsibility. The car's valve is a critical component of the machine. The clamping groove of the airlock and the lug line make up the grinding component of the device. When it comes to ensuring that the engine is operating at peak efficiency, the quality of the valve plays a critical role.

There are three types of engine valves: valve head, valve seat, and valve stem.

1. Valve head

The temperature of the valve head is very high (For the intake valve it is between 570 and 670 degrees Celsius and for the exhaust valve is between 1050 and 1200 degrees Celsius). However, because of the pressure of the gas, the force of the valve spring, and the inertia force of the transmission component, the lubrication and cooling conditions of the valve are poor. Because of this, the valve needs a certain level of strength, stiffness, heat resistance, and wear resistance.

Flat top, spherical top, and horn top are the three different shapes that the valve head may take. In most cases, flat tops are used. The flat-top valve head has a basic construction, which makes it easy to manufacture, it also has a small heat absorption surface, has a small mass, and it may be used with intake and exhaust valves. It is possible to use spherical top valves for exhaust valves because they have great strength, low exhaust resistance, and a favourable impact on eliminating exhaust gases. On the other hand, they have a wide heating surface, a big mass and inertia, and complicated processing. The horn type has a certain streamlining and can lower the intake resistance. However, this type's head heating area is considerable and only appropriate for the intake valve.

2. Valve seat

The combustion chamber and the air route are separated by the valve seat, which is a barrier. In addition, heat travels in the opposite direction, from the valve to the cylinder head, through this location. The surface of the valve seat makes contact with the cylinder head valve seat ring whenever the valve is in its closed position.

3. Valve stem

The valve stem extends from the groove where the valve lock clamp is fastened to the point where the inner fillet transitions into the oil-scraping edge. The valve stem is chrome coated to reduce valve stem wear. The angle formed between the valve seat and a plane perpendicular to the valve stem is referred to as the valve seat angle. The angle of the valve seat also affects sealing and wear.

Conclusion

If you're interested in learning more about Garima Global's engine valve or engine head gasket, you can contact us to get more information.

Comments

Post a Comment