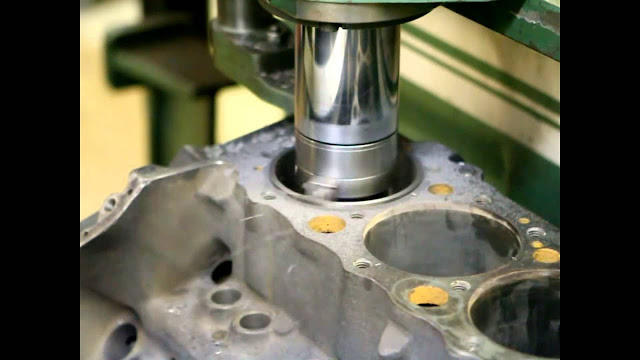

The engine block houses or houses all of the primary engine components. The cylinder bores, for example, are machined to exact tolerances. They need to be thick enough to withstand the pressure created by the burning fuel mixture. Some gas escapes through the piston rings if the cylinder becomes oval due to wear.

Types of Cylinder liners

The cylinder liner, also known as the cylinder sleeve, is a sliding surface for the piston rings inserted into the engine block as the inner wall of a cylinder, maintaining the lubrication inside. The material utilized for cylinder liners is cast iron. Dry, wet, and finned cylinder liners are the three kinds of liners.

The cylinder liners for dry cylinders are thin. They do not affect the engine coolant. Instead, they form a tight fit with the cylinder block's jacket to protect the piston from heat and contaminants.

The engine coolant comes into close touch with wet cylinder liners. Tiny holes are sometimes added to the wet cylinder liners to distribute the heat and contaminants. Water-jacket liners, which are merely a form of wet cylinder liner, are what these liners are called.

For air-cooled engines, finned cylinder liners are used. They work similarly to the dry cylinder liner in that the motor is cooled by air. On the other hand, these liners are equipped with small fins that enable inflowing air to pull a large amount of force around the cylinder, providing cooling.

Air-Cooled Blocks and Their Types

Air Cooled Cylinder Liners are created using a unique wear-resistant, fine-grained iron casting for extended life and effective cooling.

As the name implies, Air Cooled Liners are explicitly made for air-cooled engines. Cars are most typically equipped with air-cooled liners.

It works in the same way as a dry cylinder Liner, except, in this case, the cooling medium is air. The heat dissipation of the air-cooled liner is accomplished through forced convection and the fins affixed to its surface. The Fin's material has a high heat conductivity in most cases.

The Capacity of Production:

- 50000 units per month

- Specifications of the product

Dimension

- A wide range (in mm)

- Bore Diameter: 55-200mm Outer Diameter: 60-230mm

- Micron Length: 110 to 300 Microns Structure

- Types of graphite: "A" and "B" ("D" & "E" Random)

- 4-6 micron flake size

- Matrix Lamellar Pearline

Quality Assurance

- Free Ferrite Less Than 5%

- Batch-wise Material Evaluation

- 100 percent Microstructure Test Dimensional Verification

- Check for Angle Honing

- Hardness Test for Profiles

- Test of Tensile Strength

Furthermore, the forms of this structure create several parallel circular flow passageways via which the cooling fluid is conducted in parallel courses around the top section of each of the cylinders from one side to the other.

Cylinder liner manufacturers produce high-quality parts for small, big, and medium cars. They provide a large selection of personal automobiles, two and three-wheelers, and commercial vehicles such as trucks, tractors, and light commercial vehicles. Liner manufacturers always manufacture parts for large-scale industrial equipment such as ammonia compressors, forklifts, and heavy earthmovers.

Comments

Post a Comment