Engine valves are mechanical components in internal combustion engines that enable or limit fluid or gas flow to and from the combustion chambers or cylinders during operation. Choosing the correct valve, as standard as they are, may be time-consuming and difficult.

This blog will tell you seven things that you should consider While Selecting The Right Engine Valve from engine valve manufacturing companies in India.

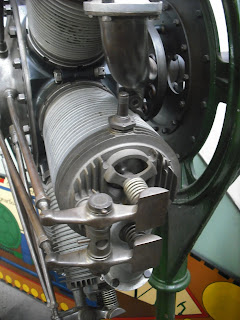

- Structural characteristics

Because of its up-and-down popping motion, most engine valves are constructed as poppet-style valves, with a conical profile valve head that fits against a machined valve seat to secure off the portion of fluids or gases. The valve stem and valve head are the two most important components. A fillet in the head leads to a seat face that is machined at an angle to match the machining on the valve seat. The seating valve face provides the seal for the valve against combustion pressure to the valve seat.

By providing a force to move the stem against the seating pressure generated by a valve spring, the valve stem connects the valve to the mechanical mechanisms in the engine that operate the valve.

Valve Type

Because of its shape, the mushroom valve is also known as the poppet valve. It's utilised to regulate the amount and timing of gas flow into an engine. In a car engine, this is the most commonly used valve. The name "poppet valve" comes from the fact that it pops up and down.

It is made up of a stem and is ahead. Because it must fit with the valve seat for optimum sealing, the valve face usually is machined exactly with an angle of 30° to 45°. The stem has a spring retainer lock groove for up and down valve movement, and its end is in contact with the cam. A pressure differential in the exhaust helps to seal the valve. The pressure differential allows open intake valves.

As the name implies, the sleeve valve is a tube or sleeve that rotates/slides between the piston and the cylinder wall in an internal combustion engine's cylinder. At the appropriate moments in the engine's cycle, ports on the side of the sleeves aligned with the cylinder's inlet and exhaust ports.

The inner cylinder barrel in which the piston slides is formed by the inner surface of the sleeve. By the periodic coincidence of ports cut in the sleeve with ports created through the central cylinder casting, the sleeve is in continuous motion, allowing and driving out the gases.

Rotary valves come in a variety of shapes and sizes. The disc type rotary valve is depicted in the diagram. It is made up of a revolving disc with a port. It connects with the inlet and exhaust manifolds alternately while rotating.

Valve Sizing and Performance Specifications

Custom-made engine valves that are appropriately proportioned last longer than valves that are unsuitable or poorly sized. Flow should continue as if there is no valve in the line when the valve is open. The flow constriction changes with the changing space between the plug and seat, making flow control valve sizing more difficult.

The valve flow coefficient (Cv), also known as the valve characteristic, chooses the correct valve size while keeping the flow steady.

Cv = (Flow) x m (Specific gravity of the media at flowing temperature/pressure drop)1/2 is a simple equation to calculate Cv.

Materials of construction

Understand the standards for chemical compatibility. The materials used in valves must be compatible with the gases or liquids that pass through them. Plastic valves frequently outlast metal valves when it comes to severe or corrosive chemicals.

Because of the lower operating temperatures, intake valves are usually composed of chrome, nickel, or tungsten steel. More heat-resistant metals, such as nichrome, silicon chromium, or cobalt-chromium alloys, may be used in higher-temperature exhaust valves. Valve faces exposed to high temperatures are occasionally strengthened by welding Stellite, a cobalt and chromium alloy, to the valve face. Stainless steel, titanium, and tribally alloys are among the other materials utilised to make engine valves.

Valve Actuation, Connections and Certification

Specific norms, standards, and restrictions apply to certain sectors and applications. It must satisfy or be certified to particular standards before a valve can be used within a specific boiler, pressure vessel, oil & gas refinery, nuclear, or other mission-critical applications (ASME, API, NACE, etc.).

Performance requirements

Determine the required pressure and temperature. Determine the temperature and pressure range for the valve's installation. Metal valves are more resistant to heat and pressure than plastic valves. For pressured gases, metal valves are usually the best option. This is because they are more durable than plastic valves.

Maintenance

Don't forget about routine maintenance. Any valve selection should take into account the maintenance needs. This is critical for valve dependability as well as application stability. The type of valve connection impacts the ease and speed with which it can be repaired or replaced.

Comments

Post a Comment