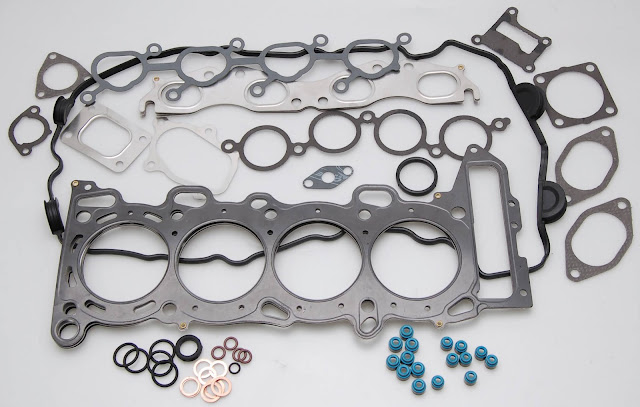

Most industries use gaskets to seal various parts of the machines to prevent leakage of liquids or gases. Gasket kits manufacturers produce gaskets of different sizes and shapes, but they come in a round shape in most cases. The material of the gaskets is essential because of the variation in chemical and temperature resistance. Depending on their purposes, various industries will require gaskets of different materials.

Let's look at how various industries use gaskets.

Aerospace

Fuel caps, the fuel system, the gascolator, and the valve covers all require gaskets in the airline industries. The most commonly used materials are rubber and silicone gaskets.

Agriculture

Agriculture is made of various farming machines. Gaskets are used to seal multiple parts of these machines to prevent oil and fuel leakage. Examples of agricultural machines that require gaskets include combined harvesters, tractors, mowers, sprayers, etc.

Automotive

These industries cannot operate without gaskets. They are used to seal various parts of the engines and fuel systems. They mostly use non-asbestos gaskets because they can withstand the pressure and temperature in most automotive machines.

Defence

There are various machines found in defence industries. Gaskets are used to seal multiple parts of these machines and prevent leakage of oil and fuel.

Domestic Appliances

Gaskets are also used in homes. They are used to seal various parts of household machines. A good example of home machines that use gaskets includes washing machines, fridges, dishwashers.

Railway

This is another industry that cannot operate without the use of gasket kits. Both Steam trains and electric trains require gaskets to seal various parts of the engines. They also use non-asbestos gaskets like automotive industries.

Maritime

Marine industries require gaskets to seal the engines' fuel caps and oil caps in ships and submarines.

Water Company

This industry is the leading market of gaskets. The water supply system requires gaskets to seal valves, water pumps, and pipe joints. Water gaskets are made from non-toxic materials to prevent water contamination. The most approved materials for water gaskets are the EPDM, FFKM, and Viton.

Petrochemical

Non-asbestos gasket material is often used in this industry. In a volatile environment, quality and safety are of the utmost importance. High-grade rubbers such as nitrile, Viton, silicone, and PTFE are employed because they are resistant to fuel, oil, and corrosion. In high-corrosion conditions, rubber quality is critical. A proper supply of high-quality materials ensures seal effectiveness. PTFE is a chemically resistant substance with a low coefficient of friction.

Pharmaceutical

When it comes to pharmaceuticals, silicone rubber seals are often used. Because of its minimal bacterial growth and clean lining, PTFE elastomer gasket kits are often used. To protect uneven seams against harsh chemicals, expanded PTFE is employed to seal these parts. In some situations, modified PTFE gaskets are used to enhance the capabilities.

Electrical

These industries require gasket kits that are UV resistance and non-asbestos. The gaskets are used to seal various parts of electronic machines. The most commonly used elastomer is Viton, EPDM, and silicone.

Bottom line

Gaskets play a very vital role in most industries. Different industries operate under different environmental conditions; therefore, the effectiveness of the gaskets will depend on the material used. Most gasket kits manufacturers ensure there is a ‘recommended use’ manual for the user.

Comments

Post a Comment